dolt

Well-Known Member

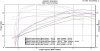

33pmg after this last trip. I changed from SE air filter to the KN filter and put in the quiet baffles. I expected a bit of a change from the baffles since I was restricting airflow but 33 is way too low on a stage 1, IMO.

You are right about mileage; a tuned Stage I TC88 should see 44-48 mpg depending on terrain and how it is ridden; tuned being the operative word. My brother gets 42-46 from his 95" with stock heads and SE203 cams. I get about 40 from my 95" with worked heads and TW44G cams but I ride a bit more aggressively than my brother does.

Regardless of what you do, I cannot over emphasize the importance of a dyno tune.:s