You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Compensating sprocket comes loose

- Thread starter Pkramer

- Start date

dolt

Well-Known Member

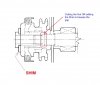

What model year? If an early model, pre '07, take the comp nut to a machine shop and have .030"-.040" shaved off the end of the nut. Common problem with early models and factory tolerances. Although the specified torque may be applied, sufficient clamping pressure may not be applied and so the comp nut can work itself loose over time. HD used to sell spacers to remedy this problem but I doubt if any are still available since the new style comp was introduced. Check out the attachment for a better explanation.

Attachments

Do it sooner than later. On my 05 Ultra the comp nut would't hold the torque value and subsequently I had some pretty significant damage.

Extended warranty covered the repair minus my deductible.

Extended warranty covered the repair minus my deductible.

dolt

Well-Known Member

I have a 79 shovelhead . And I did replace the stator and rotor and I think I have the spacing right but the new parts were not as wide so I spaced it as close as I could

. It looked good. I'll try taking ac1/16th off the nut.

Shovel configuration is different but shaving the comp nut might solve the problem, along with some red Loctite. A .060" cut might not be necessary; .030" works on the TC88 comps.

dolt

Well-Known Member

Does the compensating sprocket nut bottom out on shaft when tight

No. If it does the required clamping pressure may not be applied; hence the shim or shortening the comp nut to prevent bottoming out.

It wants to bottom out on the shoulder of the bolt

To the end of the shaft extension

To the end of the shaft extension

No. If it does the required clamping pressure may not be applied; hence the shim or shortening the comp nut to prevent bottoming out.

dolt

Well-Known Member

It wants to bottom out on the shoulder of the bolt. To the end of the shaft extension

Well, like I said in my previous, if the comp nut bottoms out on the shaft, the specified torque can be applied to the bolt; however, the necessary clamping pressure may not have been applied which will allow the comp nut to back off and loosen up.

My disclaimer is that I have no experience with shovel heads; however, from the parts diagram it appears that the shovel head compensator, while different from the twin cam, uses a similar comp nut that could bottom out on the shaft before proper clamping pressure can be applied. Shave .030"-.060" off the nut, apply some red Loctite, torque the nut down and see if that solves the issue. What have you got to lose by trying?